Printing Vs Hot Stamp . whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. Heat, pressure not viable options for some substrates. advantages of cold foil printing vs. Hot stamp printing can help companies improve product value and advertising effects. The pressing process is conducted by either an air cylinder. hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a.

from www.taymer.com

This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. Heat, pressure not viable options for some substrates. hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. advantages of cold foil printing vs. Hot stamp printing can help companies improve product value and advertising effects. whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. The pressing process is conducted by either an air cylinder.

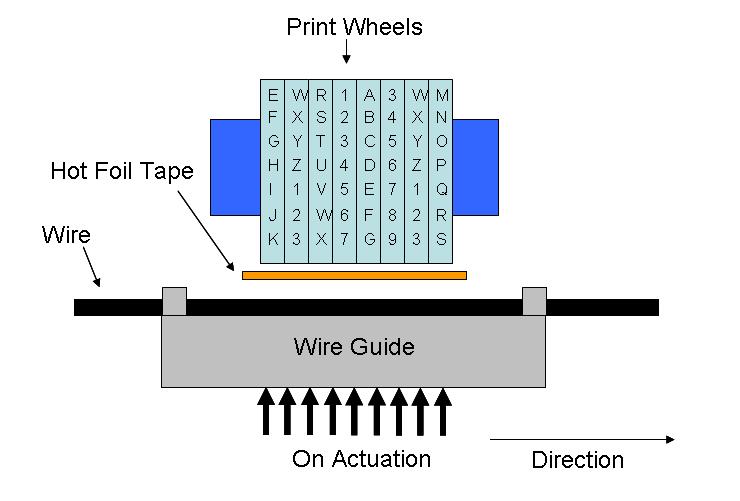

Hot Stamp Printing on Cable Technology Taymer International Inc.

Printing Vs Hot Stamp whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. advantages of cold foil printing vs. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. Heat, pressure not viable options for some substrates. The pressing process is conducted by either an air cylinder. Hot stamp printing can help companies improve product value and advertising effects.

From packhelp.com

Hot Stamping in Packaging Design Add a Little Elegance Packhelp Printing Vs Hot Stamp hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and. Printing Vs Hot Stamp.

From www.rigidbox-machine.com

Automatic Hot Stamping Printing Machine Printing Vs Hot Stamp foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. Hot stamp printing can help companies improve product value and advertising effects. . Printing Vs Hot Stamp.

From www.pinterest.com

Embossing Hot Foil Printing Hot Foil Stamping Hot Foil Stamping Design Foil Blo… Foil Printing Vs Hot Stamp hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and. Printing Vs Hot Stamp.

From www.expressprint.com.sg

Customized Label Stickers with Hot Stamping Printing Vs Hot Stamp Heat, pressure not viable options for some substrates. hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. Hot stamp printing. Printing Vs Hot Stamp.

From speccyjam.com

Screen Printing vs Heat Transfer, Which Method Works Better? Printing Vs Hot Stamp This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. Hot stamp printing can help companies improve product value and advertising effects. advantages of cold foil printing vs. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. The. Printing Vs Hot Stamp.

From www.interestingfacts.org

How Does Hot Stamp Printing Work Printing Vs Hot Stamp whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. advantages of cold foil printing vs. Hot stamp printing can help companies improve product value and advertising effects. The pressing process is conducted by either an air cylinder. foil stamping, also known as hot foil stamping or foil printing,. Printing Vs Hot Stamp.

From www.alibaba.com

Hot Stamping Foil Code Machine Print Ribbon Hot Stamping Foil 25mm 122m Hot Stamp Ribbon Buy Printing Vs Hot Stamp hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. Hot stamp printing can help companies improve product value and advertising effects. whether for paper. Printing Vs Hot Stamp.

From packhelp.com

Hot Stamping in Packaging Design Add a Little Elegance Packhelp Printing Vs Hot Stamp Hot stamp printing can help companies improve product value and advertising effects. The pressing process is conducted by either an air cylinder. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. Heat, pressure not viable options for some substrates. hot stamping is. Printing Vs Hot Stamp.

From printindooffset.com

Hot Stamping Vs Cold Foil Printing PT Printindo Utama Printing Vs Hot Stamp This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. Heat, pressure not viable options for some substrates. whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. foil stamping, also known as hot foil stamping or foil printing, is a. Printing Vs Hot Stamp.

From www.taymer.com

Hot Stamp Printing on Cable Technology Taymer International Inc. Printing Vs Hot Stamp advantages of cold foil printing vs. Heat, pressure not viable options for some substrates. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. The pressing process is conducted. Printing Vs Hot Stamp.

From www.youtube.com

HOT STAMPING FOIL Catalogue Preview YouTube Printing Vs Hot Stamp hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. Heat, pressure not viable options for some substrates. Hot stamp printing can help companies improve product value and advertising effects. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”). Printing Vs Hot Stamp.

From cejporbc.blob.core.windows.net

Gold Foil Debossing at Jerry Thornton blog Printing Vs Hot Stamp hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. advantages of cold foil printing vs. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. foil stamping, also known as hot foil stamping. Printing Vs Hot Stamp.

From www.thecopyboy.com

Hot Stamping The Copy Boy Printing Vs Hot Stamp This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. Heat, pressure not viable options for some substrates. The pressing process is conducted by either an air cylinder. whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. hot (foil) stamping. Printing Vs Hot Stamp.

From www.youtube.com

Digital hot stamping for leather YouTube Printing Vs Hot Stamp whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. foil stamping, also known as hot foil stamping or foil printing, is a printing technique where foil is applied to another material to achieve a. Heat, pressure not viable options for some substrates. hot stamping is a versatile, precise,. Printing Vs Hot Stamp.

From www.mrtakeoutbags.com

Food Packaging Printing Explained Printing Vs Hot Stamp advantages of cold foil printing vs. Heat, pressure not viable options for some substrates. hot stamping is a versatile, precise, and efficient method for printing on surfaces, and is often used to personalize or decorate products. Hot stamp printing can help companies improve product value and advertising effects. foil stamping, also known as hot foil stamping or. Printing Vs Hot Stamp.

From theribbonprintcompany.com

Ribbon Printers Thermal Transfer vs. Hot Stamping The Ribbon Print Company Printing Vs Hot Stamp hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. This pressed type deforms the material and causes engravings, while the pigment adheres to the material due to heat. The pressing process is conducted by either an air cylinder. whether for paper coating, offset printing, gravure printing, flexographic. Printing Vs Hot Stamp.

From www.hopinc.com

Cold Foil Printing vs. Hot Foil Stamping Printing Vs Hot Stamp whether for paper coating, offset printing, gravure printing, flexographic printing, or screen printing there is a perfect solution. The pressing process is conducted by either an air cylinder. Hot stamp printing can help companies improve product value and advertising effects. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment. Printing Vs Hot Stamp.

From www.echosuppliesmachine.com

H241B Hot Foil Stamp Coder/Code Printing Machine/Hot Stamp Ribbon Printer Printing Vs Hot Stamp Hot stamp printing can help companies improve product value and advertising effects. hot (foil) stamping printers create prints on a material by pressing a heated metal piece (“type”) and pigment onto it. The pressing process is conducted by either an air cylinder. advantages of cold foil printing vs. foil stamping, also known as hot foil stamping or. Printing Vs Hot Stamp.